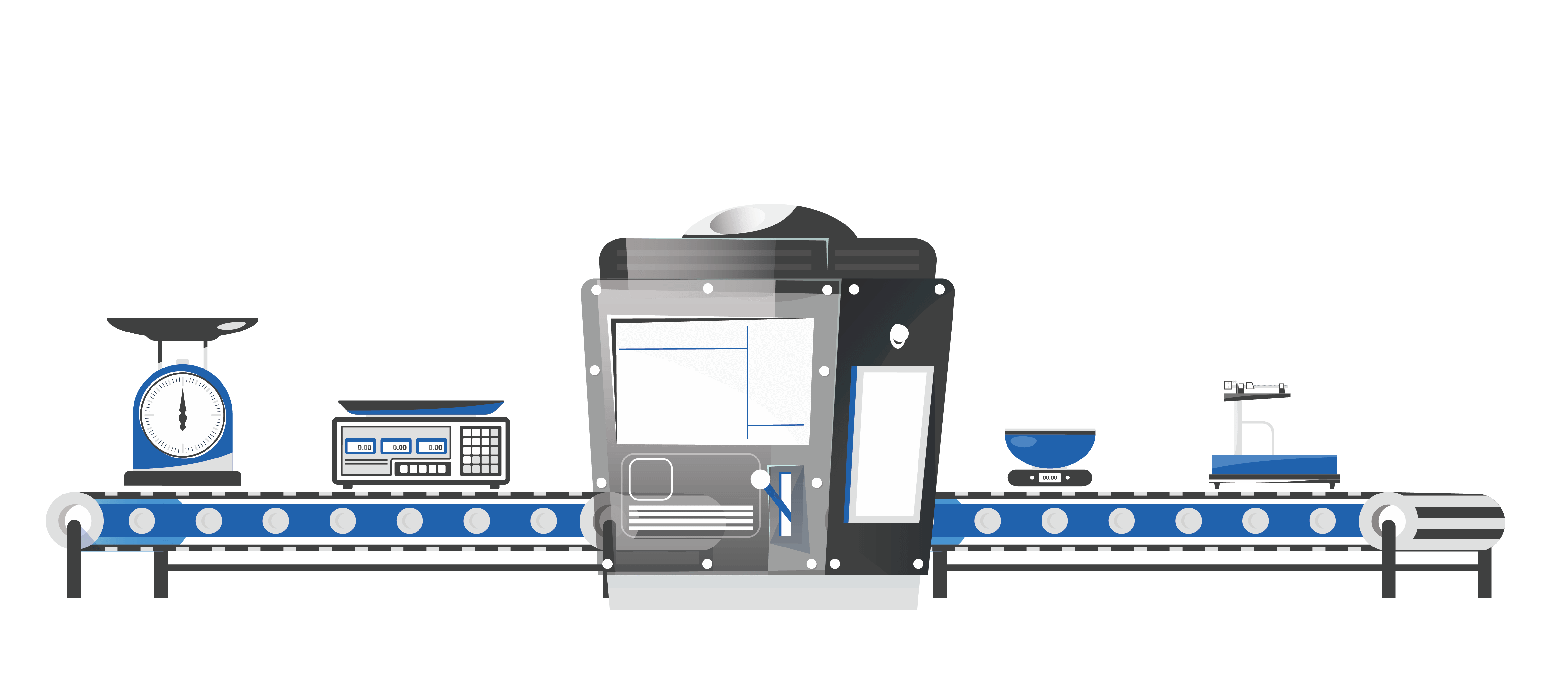

Check Weigher

These are automatic or manual machines used at the end of production or packaging line to determine if the weight of a packaged commodity is within the specified range. This helps meeting the weight compliance. We have different types of check weighers available:

- Standard Check Weigher – The major application of this product revolves around packed products like bags, cans, pouches, bottles, etc.

- Check Weigher for heavy objects – If the weight of the packets would likely go beyond 25 kgs, this device comes into picture.

- Checkweigher (Combi-Checkweigher and Metal Detector) – Is space constraint a problem and you need check weight plus detect metals as well? This product offers the best solution to the problem. Ideal location for the device is where check weighing and metal detection is in the same line.

- Sorting check weigher – Another product that increases efficiency and reduces the need of manpower, this is capable of sorting bulk products as per their weight.

Metal Detector

An electronic instrument designed for detecting the presence of metals in packets or free-flowing products like powder which helps in eradicating the possibility of metal contamination. Depending on the type of product under inspection, there are different types of metal detectors available.

- Metal detector for liquids – Chiefly used in food & chemical, cosmetic and pharmaceutical industries to detect metal contamination in liquids.

- Metal detector for aluminum foils – In case the products are packed in aluminum foils (like candy, instant noodles, etc.), a different metal detector is needed for proper functioning.

- Metal detector for pharmacy – This instrument is designed for usage in pharmacies.

- Conveyorized metal detector–This metal detector finds application around those products which don’t have a metallic packing – bags, bottles, etc.

- Metal detector for paste & semi solids – When the product to be inspected is in the form of a paste or slurry, a different metal detector is required to ensure consistency and accuracy.

- Gravity Fed Metal Detector – For free-flowing products like grains or powder, a gravity fed metal detector is the right choice.

X-Ray Inspection System

X-Ray Inspection Systems are devices generally utilized for detecting metallic as well as non-metallic contamination in packed or loose products.

- X-Ray for bulk products – Used for accomplishing a 360-degree inspection of the product in bulk before the final packing. The instrument finds application around products like grains, cereals, peanuts, rubber granules, capsules, tablets, dry fruit, frozen fruit etc.

- Standard X-Ray systems – This instrument is majorly used in food industries for the detection of non-metallic contamination.

- X-Ray forfisheries – In meat processing or poultry industries, this device is used for the detection of residual bone fragments.

- X-Rayfor bottles & cans – For the inspection of cans, bottles, etc., this system can be used with one or more than one beam in food industries.

Sorting Machine

- Intelligent CCD Multipurpose Color Sorter – Color sorters find great application in various industries including agriculture, food, oil, pharmaceutical, etc. They provide greater efficiency at lower costs and are capable of sorting tea, sesame, beans, melon seeds, kernel raisins, small, yellow rice, buckwheat, glass, plastic, coal, ore, peanuts,seeds, wolfberry, chinese prickly ash etc.

- Mini Full-Color Sorter – The movable devices are specifically designed for small seeds processors, coffee roasters, scientific research institutes, universities, labs etc. Using a color and shape sorting combination, mini sorter can recognize shells, split and broken commodities.